The Evolution of Kanban Development Methodology: From Toyota's Manufacturing Processes to Agile Project Management

Kanban: An Overview

Kanban development methodology has evolved from its origins in Toyota's manufacturing processes to become a widely adopted approach in agile project management. This methodology focuses on visualizing work, limiting work in progress, and optimizing flow to improve efficiency and delivery. The Kanban system provides a structured framework for managing tasks, ensuring that teams can effectively prioritize and complete work. By implementing the Kanban approach, organizations can enhance their project management practices by promoting transparency, collaboration, and continuous improvement. In this section, we will explore the evolution of Kanban development methodology, its roots in Toyota's manufacturing processes, and how it has been adapted for agile project management.

Kanban in Toyota's Manufacturing

Kanban originated as a scheduling system in Toyota's manufacturing processes, where it played a crucial role in optimizing production efficiency. The origins of Kanban can be traced back to the 1940s when Toyota implemented a just-in-time (JIT) production system. This system aimed to reduce waste and improve productivity by ensuring that each process only produced what was needed by the next process.

Origins of Kanban in Toyota

In Toyota's manufacturing context, Kanban served as a visual management tool that enabled teams to track and control the flow of materials and information. It involved the use of physical cards, known as Kanban cards, which represented specific tasks or items. These cards were used to signal when more materials were needed or when a process was ready for the next step. By implementing this visual representation, Toyota was able to create a pull-based system where work was initiated based on actual demand rather than forecasts.

Key Features of Kanban in Manufacturing

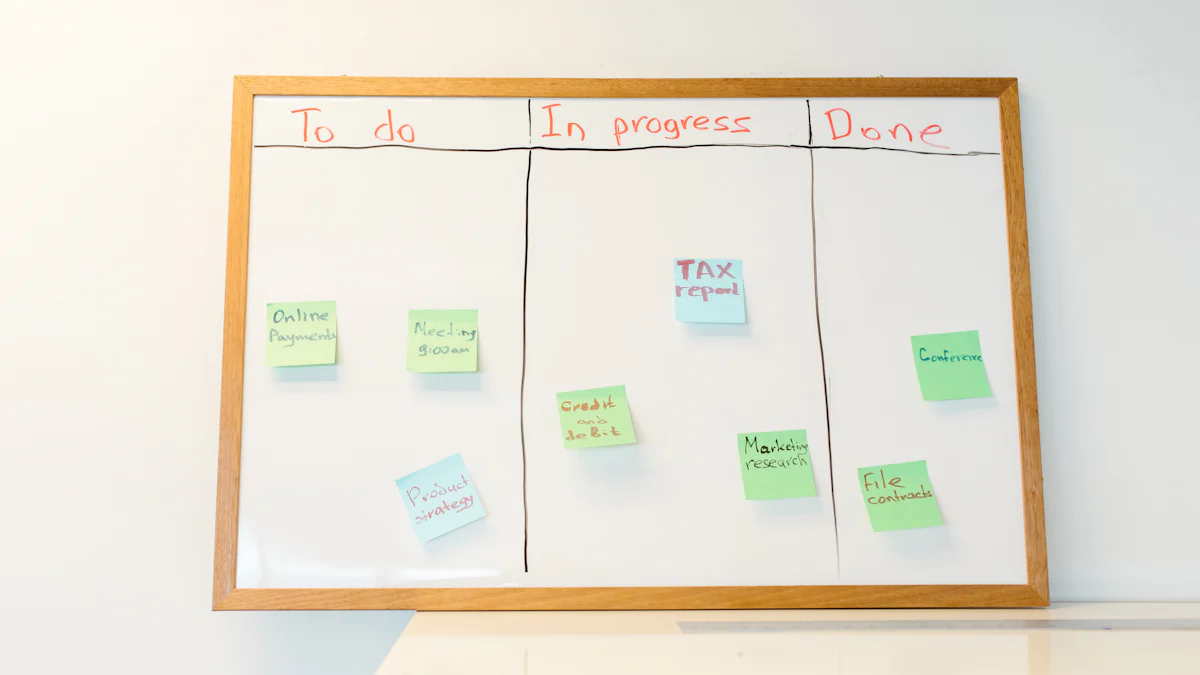

One of the key features of Kanban in manufacturing is the use of visual boards. These boards provide a clear and visual representation of work items, their status, and progress. Teams can easily see which tasks are in progress, completed, or waiting for further action. Visual boards promote transparency and enable teams to identify bottlenecks or areas that require attention.

Another important aspect is the concept of work-in-progress (WIP) limits. By setting limits on how many tasks can be actively worked on at any given time, teams can prevent overburdening themselves and maintain a steady workflow. WIP limits help avoid multitasking and encourage focused efforts on completing tasks before taking up new ones.

Continuous flow is another fundamental principle of Kanban in manufacturing. Rather than working in batches or large quantities, continuous flow emphasizes completing one task before moving on to the next. This approach minimizes waiting times between processes and reduces inventory buildup, resulting in faster and more efficient production.

Metrics-driven improvement is integral to Kanban in manufacturing. By measuring and analyzing key performance indicators (KPIs), such as cycle time or lead time, teams can identify areas for improvement and make data-driven decisions. This continuous improvement mindset allows organizations to refine their processes, optimize efficiency, and deliver higher-quality products.

Kanban in Agile Project Management

Kanban has been successfully adapted for agile project management, providing teams with a flexible and efficient approach to managing work. By incorporating Kanban principles into the agile methodology, organizations can enhance their project management practices and improve overall productivity.

Adapting Kanban for Agile

Kanban was originally developed for manufacturing processes but has found significant value in software development and other domains. In the context of agile project management, Kanban provides a visual representation of work items, allowing teams to track progress and identify potential bottlenecks. It promotes transparency, collaboration, and continuous improvement within agile teams.

Implementing Kanban in Agile

Implementing Kanban in agile projects involves visualizing work on a Kanban board, which typically consists of columns representing different stages of the workflow. Each work item is represented by a card that moves across the board as it progresses through the workflow. This visualization helps teams understand the status of each task and enables effective prioritization.

Work-in-progress (WIP) limits are also crucial in implementing Kanban in agile projects. By setting WIP limits for each column on the Kanban board, teams can prevent overloading themselves with too many tasks at once. This ensures that work flows smoothly through the system and reduces multitasking, leading to improved focus and faster delivery.

Continuous flow is another key aspect of implementing Kanban in agile projects. Rather than working on multiple tasks simultaneously or in large batches, teams focus on completing one task before moving on to the next. This approach minimizes context switching and improves efficiency by reducing waiting times between tasks.

Metrics-driven improvement plays a vital role in driving progress within agile projects using Kanban. By measuring key performance indicators (KPIs) such as cycle time or lead time, teams can gain insights into their performance and identify areas for improvement. These metrics help teams make data-driven decisions to optimize their processes continually.

Future Trends and Applications of Kanban

As Kanban continues to evolve, several future trends and applications are emerging that have the potential to further enhance its effectiveness in various domains.

Integration with Artificial Intelligence

The integration of Kanban with artificial intelligence (AI) holds great promise for improving Kanban practices. AI can analyze data from Kanban boards, identify patterns, and provide insights to optimize workflow management. By leveraging AI algorithms, teams can make more informed decisions regarding task prioritization, resource allocation, and process improvement. This integration has the potential to streamline operations, reduce waste, and enhance overall efficiency within organizations.

Expansion into Non-IT Domains

While Kanban has primarily been associated with software development, its principles and practices are finding applications beyond IT. In domains such as marketing campaign planning and supply chain management, Kanban offers a visual approach to managing tasks, tracking progress, and ensuring efficient workflows. By adopting Kanban methodologies in these non-IT domains, organizations can improve collaboration, increase productivity, and achieve better outcomes.

Enhanced Collaboration Tools and DevOps Integration

Advancements in collaboration tools are making it easier for teams to implement Kanban methodologies effectively. Digital Kanban boards offer real-time updates, seamless communication channels, and integrations with other project management tools. These enhanced collaboration tools enable distributed teams to work together efficiently while maintaining transparency and visibility into the workflow.

Furthermore, there is a growing trend of deeper integration between Kanban and DevOps practices. DevOps emphasizes continuous delivery by integrating development and operations teams. By combining the principles of Kanban with DevOps methodologies, organizations can achieve faster feedback loops, improved quality assurance processes, and accelerated time-to-market for their products or services.

The Evolution of Kanban: Looking Ahead

The evolution of Kanban from its origins in manufacturing to its widespread adoption in agile project management showcases its versatility and adaptability. As we look ahead, there are exciting future trends and applications on the horizon for Kanban. Integration with artificial intelligence holds the potential to enhance Kanban practices by leveraging data insights and optimizing workflow management. Additionally, Kanban is expanding beyond IT domains, finding applications in marketing, supply chain management, and more. With enhanced collaboration tools and deeper integration with DevOps practices, Kanban continues to evolve, offering organizations opportunities to enhance efficiency, collaboration, and overall project success.

See Also

Deciding Between Kanban and Scrum: Selecting the Appropriate Agile Approach for Your Project

Unveiling the Advantages of Agile Project Management: A Dive into its Flexibility

Mastering Workflow Management: A Comprehensive Guide to Utilizing Kanban Boards

Optimizing Workflow Management: A Detailed Walkthrough of Kanban Board Usage

Embracing Change in Product Design Teams: Unleashing the Flexibility of Kanban